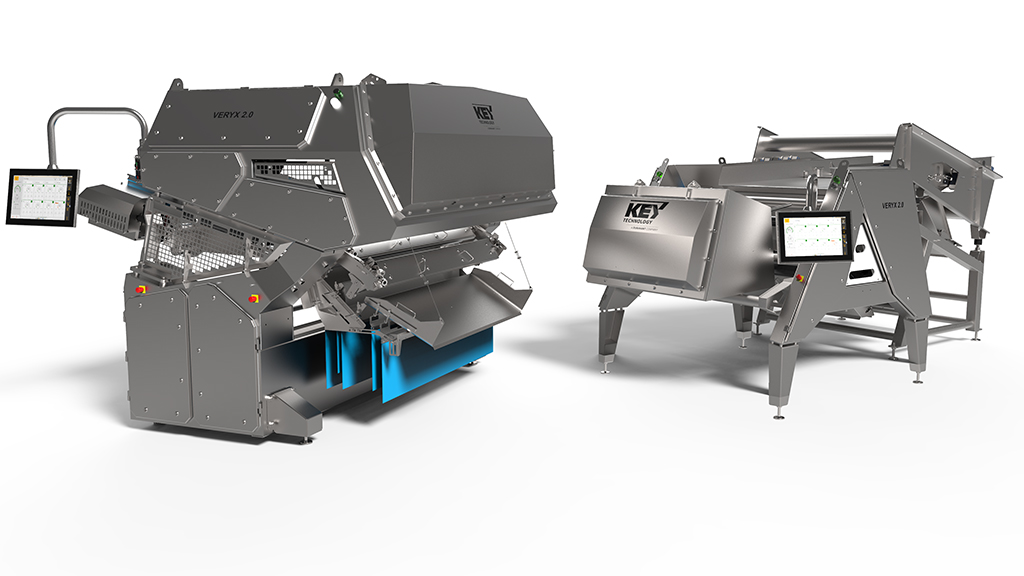

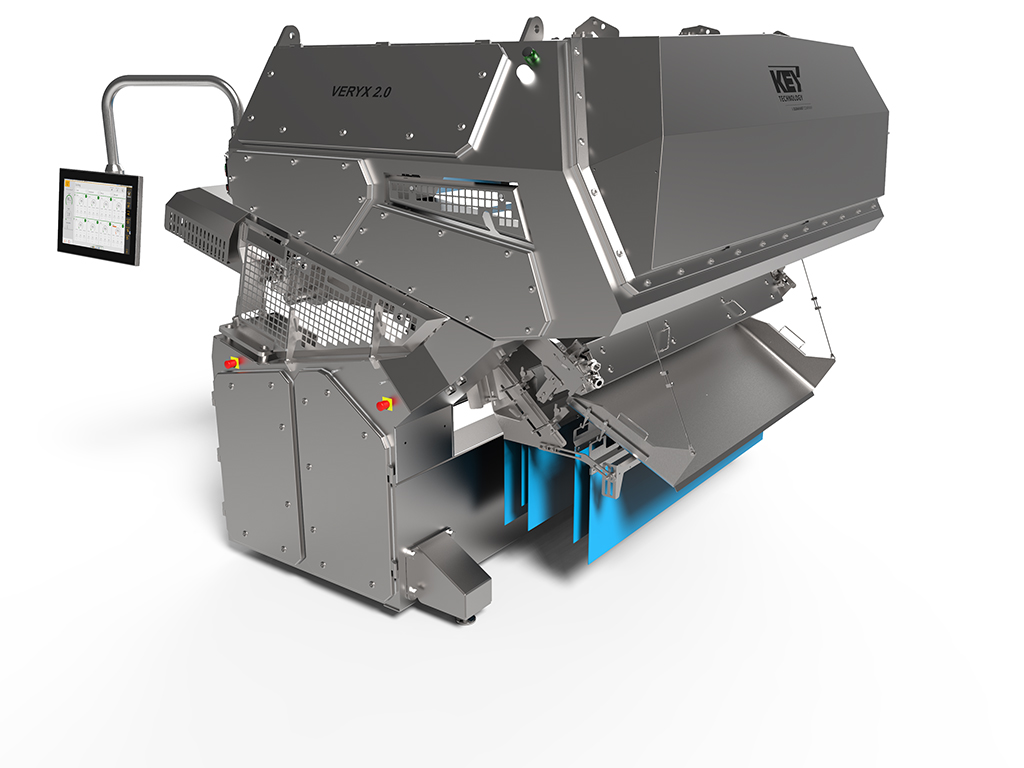

VERYX® 2.0 transforms digital sorting with a modular platform of chute-fed and belt-fed sorters to meet your unique and specific needs. With its innovative mechanical architecture and sensor technology, state-of-the-art electronic sort engine, advanced machine algorithms and rich information capabilities, VERYX 2.0 delivers a revolution in performance that defines the new standard for digital sorting.

VERYX 2.0 FEATURES & BENEFITS

Improved design for sanitation and protection of critical components

- Consistent high sort performance, including over extended production runs in challenging environments

New LED technology

- Clearer sensor images and enhanced detection of product defects

- Double the life of previous generation LEDs, reducing maintenance and operating costs

Next-gen laser sensors

- Improved removal of critical foreign materials (FM) and increased good product recovery

AI-powered software features

- FM Alert: immediate alert and documentation of critical FM findings on the line

- Next-level accuracy in measurement of product dimensions for sorting and data reporting

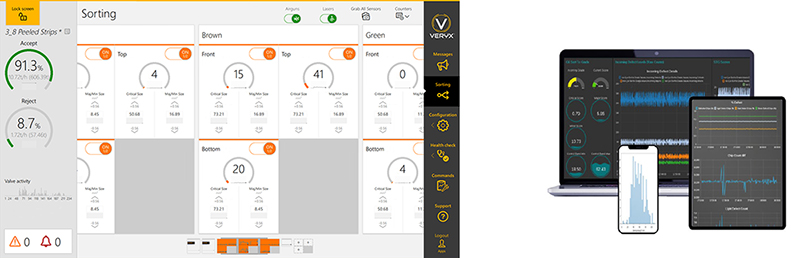

Key Discovery data analytics

- A wealth of process and product information delivered to the enterprise, unlocking insight to optimize sort operation and line efficiency

- Powerful product quality reporting capabilities

- Fully remote monitoring and management of the sort process

Key Differentiators

-

Most Accurate Detection of all Defects and FM

-

Multi-Sensor Pixel Fusion™

-

Sustained Total Product Surface Inspection

-

Advanced Machine Intelligence

-

Reduced Operator Intervention

-

Smart Self-Adjusting System Features

-

Maintains Performance at High Defect Loads

-

Predictive System Diagnostics

Resources

Variations

Overview

The Belt-Fed VERYX 2.0 is the first sorter to deliver total product inspection that is sustained throughout the production cycle. Smart features such as auto-learning, self-adjustment algorithms, predictive system diagnostics, smart alarms, FMAlert™ and Sort-to-Grade™ enable VERYX2.0 to operate virtually unattended during normal production. VERYX 2.0 can be configured for two-way or three-way sorting.

Key Differentiators

- Sustained Total Product Surface Inspection

- Cool-time Information Processing

- Simplified Maintenance and Sanitation

- 24/7 Sustained Sorting Performance - Through the Entire Production Cycle

- Intuitive User Interface - Configurable for Multiple User Levels and Views

- Remote Sorter Management Functions

Overview

With a highly innovative mechanical architecture, multi-sensor Pixel Fusion™, the highest resolution cameras and laser sensors available on a digital sorter and the most precise ejection system on the market, VERYX 2.0 maximizes foreign material (FM) and defect detection and removal while virtually eliminating false rejects, improving yield and ensuring quality.

Key Differentiators

- Simplified Maintenance and Sanitation

- Remote Sorter Management Functions

- Cool-time Information Processing

- Intuitive User Interface - Configurable for Multiple User Levels and Views

- 24/7 Sustained Sorting Performance - Through the Entire Production Cycle