The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Key Technology Introduces COMPASS® Optical Sorter for Leafy Greens

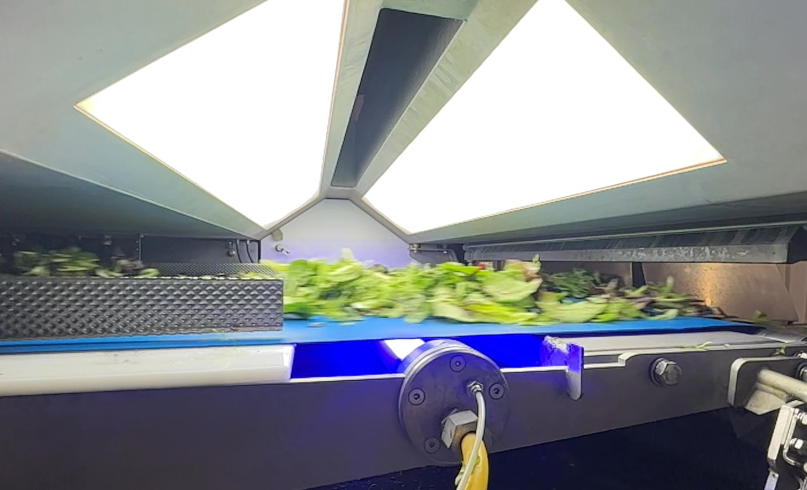

Key Technology (Key), a member of Duravant’s Food Sorting and Handling Group, introduces its COMPASS® optical sorter for leafy greens. Designed to inspect fresh-cut product straight from the field, this belt-fed system combines high-performance foreign material (FM) detection and removal with gentle, hygienic product handling. Featuring intuitive controls and an open, easy-to-clean design, COMPASS helps processors protect food safety, reduce labor requirements and achieve a fast return on investment.

“Foreign material is one of the biggest challenges at this early stage of leafy greens processing, but many processors can’t justify the expense or complexity of traditional optical sorting systems. COMPASS changes that,” said Jack Lee, Duravant Group President – Food Sorting and Handling. “It delivers accurate and reliable FM removal in a user-friendly, cost-effective solution engineered to withstand the dirt and debris common at the front end of leafy greens lines.”

Ideal for sorting spinach, arugula and other unwashed, fresh-cut leafy greens including salad mixes, COMPASS identifies and rejects a wide variety of FM including dirt clods, rocks, sticks, insects and animal parts, as well as product defects when running single varieties.

To simplify operation and reduce training requirements, COMPASS is recipe driven and features a touchscreen interface that mimics smartphone app navigation. Operators can learn to run the system in less than 30 minutes, easily create new recipes and quickly changeover between different products or salad blends. Intelligent belt control automatically maintains proper belt tracking, minimizing downtime and eliminating the need for manual adjustments.

COMPASS is equipped with customizable camera options including up to eight channels of multispectral sensor data to deliver advanced performance at a lower cost of ownership than laser-based sorters. When configured with Key’s Pixel Fusion™ detection technology, COMPASS combines visible, infrared and shortwave infrared data at the pixel level to produce optimal contrasts for finding even the most difficult-to-detect FM and product defects. An optional chlorophyll-sensitive detection channel further enhances contrast between leafy greens and FM.

Fresh-cut leafy greens are lightweight and often moist, which can cause them to clump, overlap or stick to surfaces during sorting if not properly handled. Key combines COMPASS with the ideal infeed conveying systems to effectively present product to the sorter’s inspection zone, maximizing sort accuracy. Optional air-assist systems create a controlled curtain of air that improves the transition from the infeed conveyor to the belt for gentle product flow. Air knives at discharge help carry leaves through the pass stream, minimizing the chance of good product falling short or sticking.

Key designed COMPASS for maximum sanitation and easy cleaning with an open frame, sloped surfaces and quick-release belt removal for fast washdowns. A clean-in-place system with spray bars and brushes beneath the belt maintains hygiene throughout production. High-mounted camera windows stay clean and are easily accessed for wiping. The dry-air boost system prevents condensation from collecting inside the enclosure, protecting sensors even in humid or refrigerated environments.

The open architecture provides clear visibility into the product zone. An optional counter-rotating roller prevents product buildup at the divider between accept and reject streams, keeping the discharge area clean and maintaining consistent product flow. With its cantilevered frame and open discharge area, COMPASS offers ample space for integration with collection conveyors, water flumes or other downstream equipment. For processors upgrading from Key’s legacy Optyx optical sorter, COMPASS shares the same height and length, allowing it to be seamlessly installed within existing lines.

Every COMPASS is equipped with Key Discovery™, a powerful data analytics and reporting software that transforms the sorter into an IIoT-connected device and information center, giving processors real-time insights into line performance and product quality trends.

Key supports its customers worldwide through an extensive sales network and its global service team. For more information on Key’s optical sorters, visit www.key.net/en/our-products/sorting/.

About Key Technology

Key Technology is a global leader in the design and manufacture of automation systems including digital sorters, conveyors and other processing equipment. Applying processing knowledge and application expertise, Key helps customers in the food processing and other industries improve quality, increase yield and reduce cost. Key manufactures its products in Walla Walla, Washington, USA; Redmond, Oregon, USA; and in Beusichem, the Netherlands. Key offers customer demonstration and testing services at five locations including Walla Walla and Beusichem as well as Hasselt, Belgium and Sacramento, California, USA; and maintains a sales and service office in Santiago de Queretaro, Mexico. Key is a Duravant Company. For more information, visit www.key.net.

About Duravant

Headquartered in Downers Grove, IL, Duravant is a global engineered equipment company with manufacturing, sales and service facilities throughout North America, Europe and Asia. Through their portfolio of operating companies, Duravant delivers trusted end-to-end process solutions for customers and partners through engineering and integration expertise, project management and operational excellence. With worldwide sales distribution and service networks, they provide immediate and lifetime aftermarket support to all the markets they serve in the food processing, packaging and material handling sectors. Duravant’s market-leading brands are synonymous with innovation, durability and reliability. For more information, visit www.duravant.com.

Reader Inquiries:

Buffy Hagerman

Key Technology

150 Avery Street

Walla Walla, WA 99362 USA

Tel: +1 509 540 7415

bhagerman@key.net

www.key.net

Reader Inquiries:

Lene Boes

Key Technology

Bedrijfsstraat 6b

B-3500 Hasselt, Belgium

Tel: +32 (0) 11 26 70 38

lboes@key.net

www.key.net