The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Key Technology Introduces New Auto Diverter for Vibratory Conveyors

Key Technology, a member of the Duravant family of operating companies, introduces its new and improved Auto Diverter for its popular Iso-Flo® vibratory conveyors. Ideal for bulk product and packaging distribution lines, the Auto Diverter splits the product flow to two downstream systems, such as digital sorters or packaging machines, and changes the proportion of product going to each of the two lanes as needed. This patented Auto Diverter features a stronger diverter blade, an improved pneumatic hold-down system and more to achieve longer equipment life and greater accuracy for better performance of downstream systems.

“Vibratory conveying equipment, including diverters, take a beating during routine operation. Product moves through shakers with immense force over long periods of time. For that reason, robust automatic diverters are challenging to design – most equipment manufacturers won’t even try,” said Rudy Sanchez, Process Systems Product Development Manager at Key. “We did a lot of research and testing to develop a new diverter system that improves reliability and extends the life of this unit in even the most demanding production environments. Our Auto Diverter is a very unique solution.”

Suitable for dry, frozen and wet applications, the Auto Diverter can handle virtually any free-flowing food product including fruits and vegetables such as cut and whole potatoes and cut and whole corn, as well as nuts, candies, snacks and more. Available for beds up to 1830mm (72 inches) wide, it can be equipped with a blade up to 1200mm (47 inches) long.

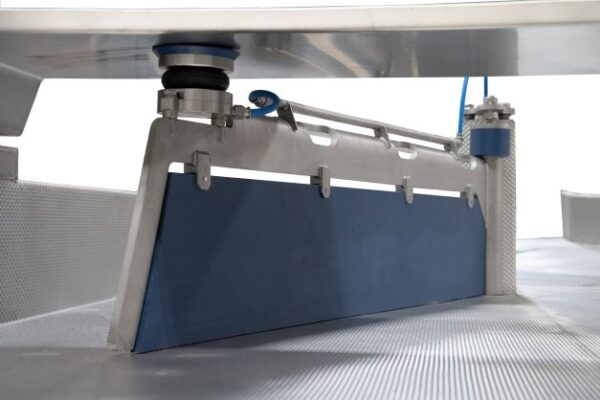

The redesigned Auto Diverter features a stronger, thicker diverter blade for better product handling and equipment longevity. Now bolted, instead of welded, the blade can be easily removed for cleaning and maintenance. The new pneumatic hold-down system anchors the blade to the surface of the bed to withstand a greater amount of product force without shifting from its programmed position. For better product control, each diverter is customized to guide product away from bed corners and features a blade that matches the product depth.

To accurately divide the product stream, the Auto Diverter’s pneumatic actuator moves the blade precisely into each position needed. Using only the controls and no manual adjustments, an operator can split the two product outfeeds and implement quick and easy adjustments including blocking an entire lane for maintenance of downstream equipment. Featuring fully-integrated and optimized controls, the Auto Diverter can be operated locally at the user interface, or via a plant-wide network and/or automatically controlled by downstream equipment.

Designed to maximize sanitation, the Auto Diverter features scalloped welds throughout its stainless-steel frame and blade. The actuator is positioned underneath the conveyor bed to help maintain food safety. Compared to traditional diverters, where an operator must manually reach over the shaker bed to reposition the blade, the Auto Diverter improves operator safety and ergonomics while reducing the risk of foreign material introduction to the product stream.

About Key Technology

Key Technology is a global leader in the design and manufacture of automation systems including digital sorters, conveyors and other processing equipment. Applying processing knowledge and

application expertise, Key helps customers in the food processing and other industries improve quality, increase yield and reduce cost. Key manufactures its products in Walla Walla, Washington, USA; Redmond, Oregon, USA; and in Beusichem, the Netherlands. Key offers customer demonstration and testing services at five locations including Walla Walla and Beusichem as well as Hasselt, Belgium; Sacramento, California, USA; and Melbourne, Australia; and maintains a sales and service office in Santiago de Queretaro, Mexico. Key is a Duravant Company. For more information, visit

www.key.net.

About Duravant

Headquartered in Downers Grove, IL, Duravant is a global engineered equipment company with manufacturing, sales and service facilities throughout North America, Europe and Asia. Through their portfolio of operating companies, Duravant delivers trusted end-to-end process solutions for customers and partners through engineering and integration expertise, project management and operational excellence. With worldwide sales distribution and service networks, they provide immediate and lifetime aftermarket support to all the markets they serve in the food processing, packaging and material handling sectors. Duravant’s market-leading brands are synonymous with innovation, durability and reliability. For more information, visit www.duravant.com.

Reader Inquiries:

Buffy Hagerman

Key Technology

150 Avery Street

Walla Walla, WA 99362 USA

Tel: +1 509 540 7415

bhagerman@key.net

www.key.net

Lene Boes

Key Technology

Bedrijfsstraat 6b

B-3500 Hasselt, Belgium

Tel: +32 (0) 11 24 91 91

lboes@key.net

www.key.net