The Duravant family of operating companies serve the food processing, packaging and material handling segments.

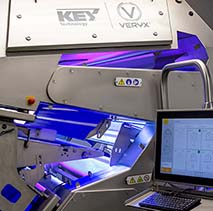

Key Technology Introduces New Sort-to-Grade Capabilities for VERYX Digital Sorters

Key Technology, a member of the Duravant family of operating companies, introduces its new Sort-to-Grade® (STG) software for VERYX® digital sorters. The patented STG software, field proven for potato strips, is now available for more food sorting applications including fresh and processed fruits and vegetables as well as nuts. Compared to traditional sorting strategies, where a series of one-off accept/reject decisions are made based on fixed selection criteria, a STG-enabled sorter dynamically evaluates each decision based on how it impacts the aggregate ‘in the bag’ grade, as defined by the processor. Controlling the output for defect categories of various severity and/or product dimensions, STG accurately delivers the most complex final product specifications without operator intervention, while increasing yields by one to three percent.

STG recognizes and categorizes the visual and structural characteristics of every individual object in the product stream. It can allow a specific amount of low- and middle-severity defects to pass, based on user-defined allowable tolerances for each defect category, while ejecting all high-severity defects and foreign material (FM). Accurately passing the maximum proportion of allowed defects for the grade, STG improves process yield. Similarly, when shape/size grading, STG manages the exact ‘in the bag’ distribution required to meet specifications, automatically accounting for variations in the size distribution of incoming product.

The smart algorithms perform complicated yield optimization calculations in microseconds and automatically adjust the sorter’s accept/reject decisions to maintain a consistent output, despite constant variations in incoming product quality characteristics. Far surpassing the abilities of any human in both decision-making sophistication and speed, STG eliminates the need for manual sort recipe adjustments while achieving the most complex final product quality specifications.

“Our powerful Sort-to-Grade software can evaluate multiple criteria at once. For example, a discoloration may be considered a defect only if it exceeds a certain absolute or relative dimension or if it occurs in combination with other defects on the same object,” said Marco Azzaretti, Advanced Inspection Systems Product Manager at Key. “Processors can eliminate mechanical size grading equipment by using a STG-enabled sorter to control products’ dimensional characteristics. The possibilities of Sort-to-Grade are endless.”

With next-generation sensors and all-surface product inspection, VERYX with STG can identify and classify each object’s color, size, shape, structural properties and/or chemical composition. To meet the allowed tolerance for the grade, STG manages specific types, sizes and locations of defects as well as color grades, if needed. When assessing dimensional characteristics, STG can control minimum or maximum length, width and area or multiple attributes at once in addition to managing the distribution of each dimension within multiple user-defined categories between the two absolutes.

Without STG, sorters make accept/reject decisions by comparing the defect, color, size and/or shape of each object to pre-determined criteria , but those decisions are made independently from each other, regardless of the final ‘in the bag’ quality results. Historically, an operator had to adjust the sorter’s accept/reject thresholds subjectively in an effort to make grade given inevitable fluctuations in the quality of the incoming product. This traditional approach to sorting can result in too many acceptable defects being rejected, creating significant yield loss. Or, when incoming defect loads spike, final grade specifications can be missed.

“The value of VERYX with Sort-to-Grade is threefold. It enables processors to address complex product specs to guarantee their quality objectives are met. At the same time, it maximizes yields by passing the ideal amount of acceptable defects, colors, sizes and shapes, all while minimizing operator intervention for better profitability,” said Azzaretti.

Key’s family of VERYX sorters includes belt- and chute-fed systems in various widths to satisfy a wide range of applications and capacity requirements.

For more information on Key’s VERYX, visit www.key.net/products/veryx.

About Key Technology, Inc.

Key Technology is a global leader in the design and manufacture of automation systems including digital sorters, conveyors and other processing equipment. Applying processing knowledge and application expertise, Key helps customers in the food processing and other industries improve quality, increase yield, and reduce cost. Key manufactures its products at its headquarters in Walla Walla, Washington, USA; Beusichem, the Netherlands; Hasselt, Belgium; and Redmond, Oregon, USA. Key offers customer demonstration and testing services at five locations including Walla Walla, Beusichem, and Hasselt as well as Sacramento, California, USA and Melbourne, Australia; and maintains a sales and service office in Santiago de Queretaro, Mexico. Key is a Duravant Company.

About Duravant

Headquartered in Downers Grove, IL, Duravant is a global engineered equipment company with manufacturing, sales and service facilities throughout North America, Europe and Asia. Through their portfolio of operating companies, Duravant delivers trusted end-to-end process solutions for customers and partners through engineering and integration expertise, project management and operational excellence. With worldwide sales distribution and service networks, they provide immediate and lifetime aftermarket support to all the markets they serve in the food processing, packaging and material handling sectors. Duravant’s market-leading brands are synonymous with innovation, durability and reliability. Visit www.duravant.com.