The Duravant family of operating companies serve the food processing, packaging and material handling segments.

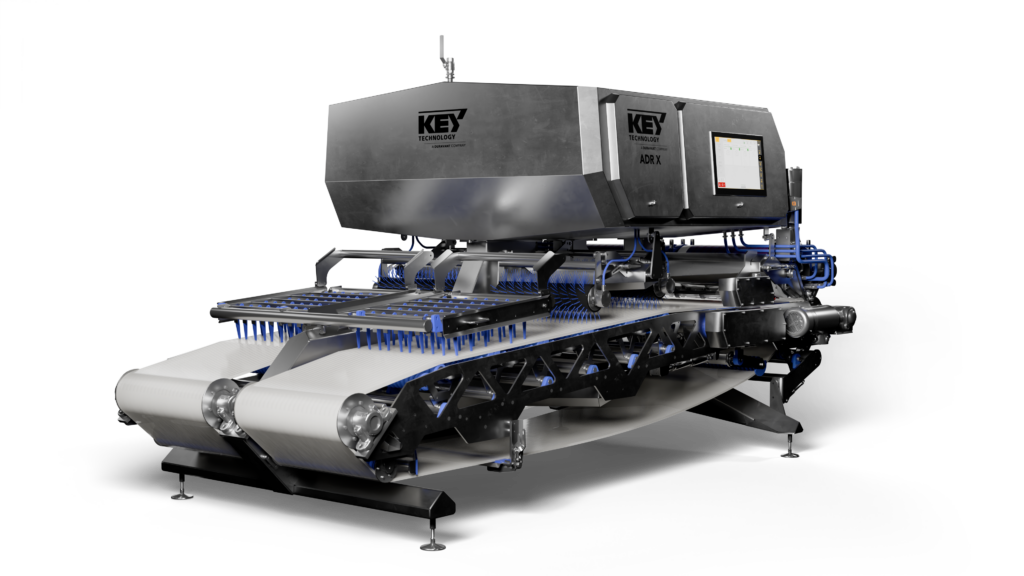

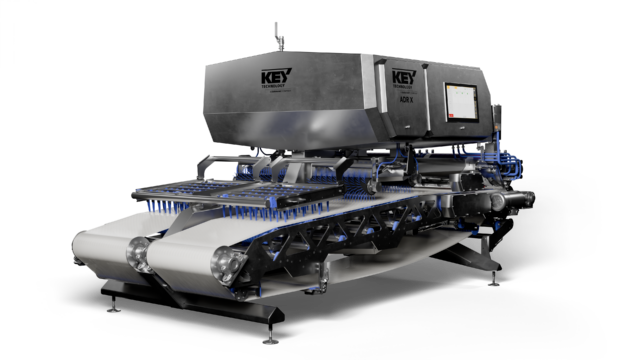

ADR X (Automatic Defect Removal)

For more than 40 years, Key Technology’s Automatic Defect Removal System (ADR) has defined the global standard for potato strip defect removal. Processing the vast majority of the world’s potato strips, ADR has earned the industry’s trust through unmatched performance and reliability.

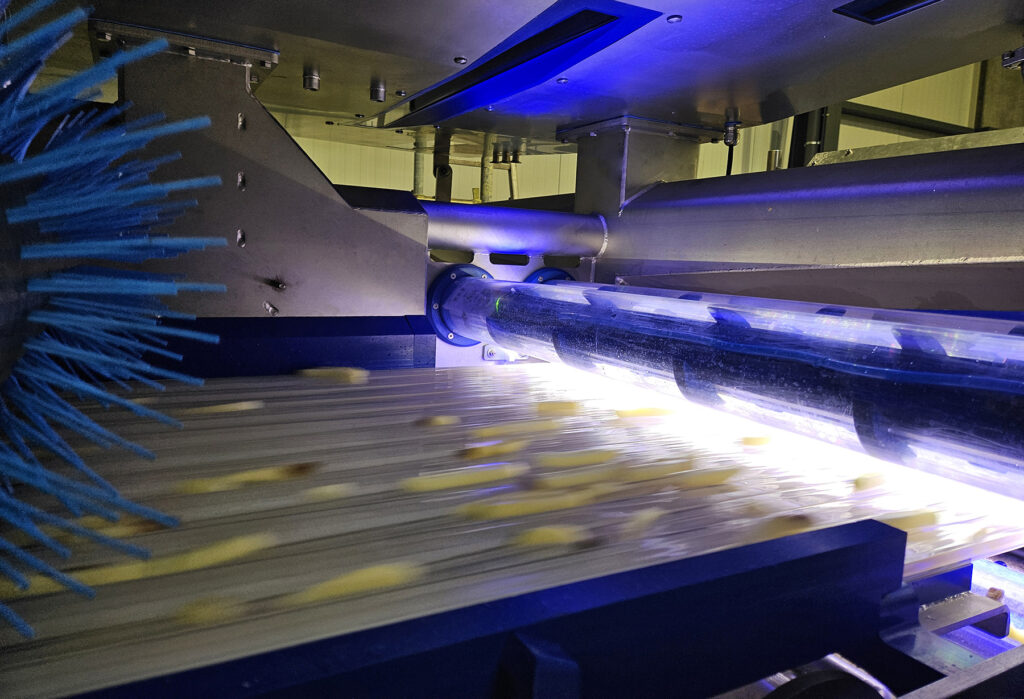

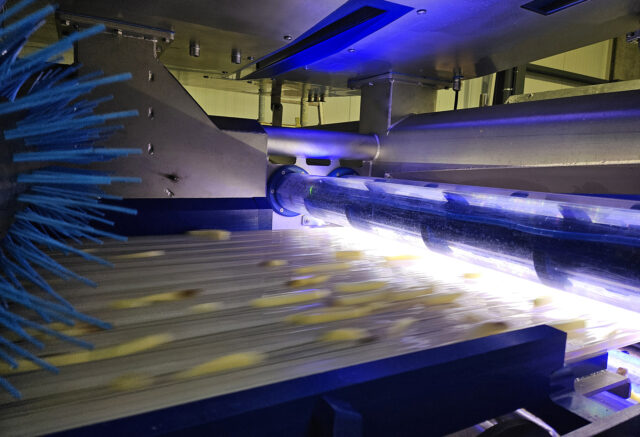

The new ADR X advances this legacy with enhanced multi-spectral sensing, powerful LED illumination and next-generation software that set a new benchmark for precision trimming and defect removal. Engineered for both peeled and peel-on wet applications, ADR X removes green discoloration and other visual defects with exceptional accuracy while preserving maximum usable product. Intelligent, recipe-driven conveying automatically adapts to different cut sizes to deliver consistent, high-capacity performance with minimal operator intervention.

With its hygienic, open design for simplified sanitation and the ability to upgrade existing ADR installations, ADR X empowers processors to elevate product quality, protect margins and lead in an increasingly competitive market — continuing Key’s four-decade commitment to innovation and operational excellence.

Are you interested in learning more about our solutions?

Key Differentiators

- True-color, intuitive user interface

- Recipe-driven automatic cut size adjustments

- Hygienic, open design for wet environments

- Up to 15 MT/Hr

- Clean-in-place (CIP) functionality

- Reinforced endless belts for reduced maintenance

- Faster belt replacement and simplified servicing

- Enhanced multi-spectral, multi-channel sensing

- Advanced LED illumination with strobing technology

- Plug-and-play installation or upgrade for existing ADR systems