The Duravant family of operating companies serve the food processing, packaging and material handling segments.

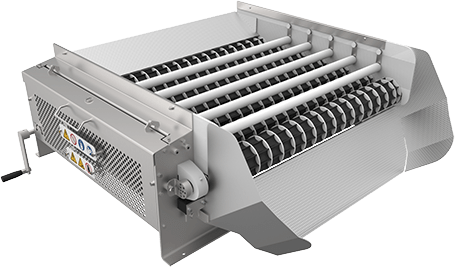

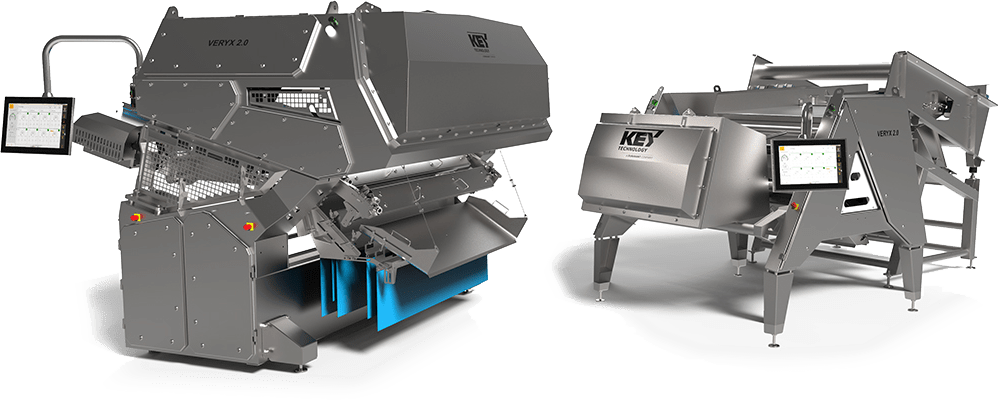

Food Sorting Machines & Processing Conveyors

Companies around the world depend on Key Technology’s high-performance for processing excellence. We collaborate with customers and prospects in our Customer Experience Centers to develop the optimal solution for their unique requirements and to demonstrate the value of our equipment.

From food processing conveyors to food sorting machines, we have extensive experience and an in-depth understanding of the needs of food processors across a wide range of industries. This enables us to configure a product solution that not only fits your application but one that meets YOUR specific requirements.

Are you interested in learning more about our solutions?