The Duravant family of operating companies serve the food processing, packaging and material handling segments.

What keeps food processing CEOs awake at night?

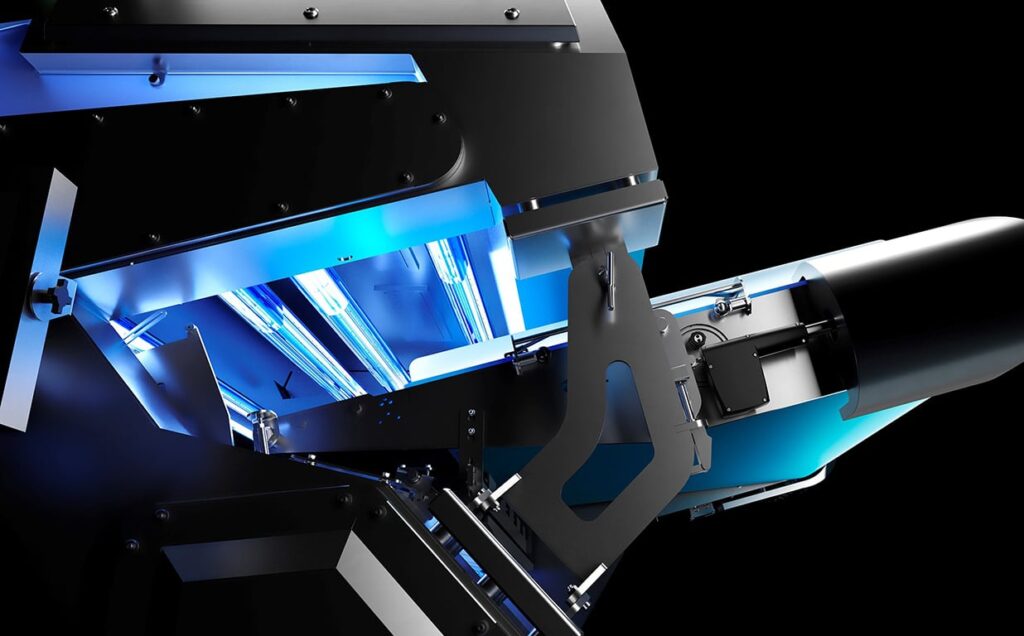

VERYX Optical Sorter

The Million Dollar Question Every Food Processor Faces: Zero Tolerance for Contamination

In today’s hyper-connected world, a single contaminated product doesn’t just affect one consumer—it can trigger a cascade of consequences that reverberates across your entire operation. Within hours, what starts as an isolated quality control issue can spiral into millions of dollars in recalls, emergency response costs, legal settlements, and irreparable brand damage that takes years to rebuild.

The scenarios are all too familiar: one glass fragment discovered in a bag of potato chips leads to a nationwide recall of your most popular product line. A single piece of plastic found in premium snack mix results in pulled inventory across thousands of retail locations. One metal shaving detected in a package of organic leafy greens generates headlines that overshadow decades of quality reputation.

These aren’t hypothetical situations—they’re realities that food processors face every day. The statistics are sobering: contamination incidents can cost companies anywhere from $1 million to $100 million, depending on the scope of the recall and the extent of brand damage. But beyond the immediate financial impact lies something even more devastating: the loss of consumer trust that your brand has spent generations building.

Attending Pack Expo? Let us know you’ll be there — we have something to show you.

The Critical Question Keeping Executives Awake

This reality has created what we call “the million dollar question” that keeps food processing executives awake at night: “How do we catch the one-in-a-million defect that could destroy everything we’ve built?”

It’s a question that demands more than traditional quality control measures. Today’s food safety challenges require precision detection capabilities that can identify microscopic contaminants at production speeds, without compromising throughput or creating unnecessary waste. The solution lies not just in having advanced technology, but in partnering with experts who understand the nuanced challenges of modern food processing.

Decades of Expertise, Proven Results

At Key Technology, our decades of experience working alongside the world’s leading food processors have given us unique insights into these critical challenges. We’ve witnessed firsthand how contamination incidents unfold, analyzed the root causes of quality control failures, and most importantly, developed innovative solutions that prevent these costly disasters before they happen.

Our deep expertise in optical sorting technologies positions us at the forefront of food safety innovation. We understand that every food category presents unique contamination risks—from foreign object detection in snack foods to defect identification in fresh produce. This specialized knowledge, combined with our proven track record of successful implementations across diverse processing environments, enables us to deliver solutions that don’t just meet industry standards—they set new benchmarks for food safety excellence.

The Future of Food Safety Awaits

The evolution of contamination detection technology has reached a pivotal moment. Advanced optical sorting systems now offer unprecedented precision, combining artificial intelligence, machine learning, and sophisticated imaging technologies to identify contaminants that were previously undetectable.

Join Us at Pack Expo 2025

If you’re attending Pack Expo this year, we invite you to discover how our latest innovation continues to revolutionize contamination detection for food processors worldwide. Our team will be on-site to demonstrate technology that could transform your approach to food safety.

Let us know you’ll be there — we have something to show you.