Food processing often requires the product flow to be separated into multiple streams for efficient processing.

Distribution conveyors control product flow to downstream equipment using gates and diverters to meter the product by the optimal amount.

Explore the variety of conveying technology we offer below.

""KEY’S ABILITY TO CUSTOMIZE AND THE EXPERTISE OF THEIR STAFF HAVE BEEN INSTRUMENTAL TO OUR SUCCESS. THEIR TECHNOLOGY IS CLEARLY AT THE FOREFRONT AND WE COULDN’T BE HAPPIER."" - Bob Lowder, Manager of Capital Engineering & MRO Programs, Ocean Spray Cranberry

Key Differentiators

-

Gate and Diverter Options to Meet Your Needs

-

Exceptional Durability & Reliability

-

Lowest Total Cost of Ownership

-

Unmatched Design and Engineering Experience

-

Hygienic Surface Finishes Resist Bacterial Growth

-

Custom Designs From Simple to Complex

-

Designed for Sanitation

Variations

Overview

Zephyr provides gentle, high-capacity and low maintenance conveying for processors of frozen, fragile, seasoned, breaded or coated products.

Key Differentiators

- Gentle Product Handling Minimizes Seasoning Loss and Product Damage

- High Throughput - Moves Product at Rates Up to 12.2 Meters (40 ft) per Minute

- Gate and Diverter Options to Meet Your Needs

- Low Maintenance - Patented Drive is Designed for Long Life

- Drive Located Anywhere Along Pan Length

- Easy to Clean - Flat Surfaces, Simple Wipe-Down Cleaning

- Continuous Self-Cleaning Action Prevents Build Up, Mixing and Size Separation

- Custom Designs From Simple to Complex

Overview

Impulse® performs with flexible conveying speeds and accurate distribution control, while providing a quiet conveying solution and a low operating cost.

Key Differentiators

- Gate and Diverter Options to Meet Your Needs

- Precise Metering - Instantaneous Start and Stop

- Custom Designs From Simple to Complex

- No Moving Parts - No Belts, No Bearings, No Lubrication

- Self-Regulated Performance for Varied Processing Conditions

Overview

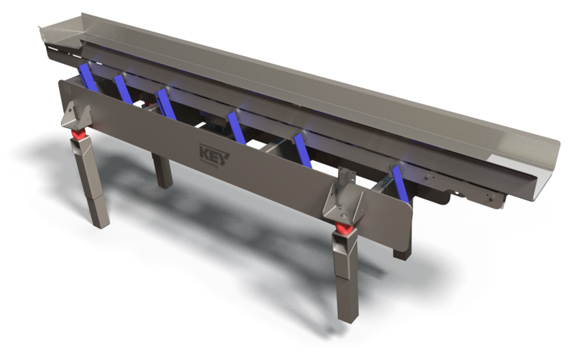

The Iso-Flo distribution conveyor provides optimal spreading of the product to facilitate accurate distribution of product.

Key Differentiators

- Gate and Diverter Options to Meet Your Needs

- Custom Designs From Simple to Complex

- Lowest Total Cost of Ownership

- More Than 25,000 in Use Globally

- StrongArm Spring Technology Requires Fewer Arms with 3X the Life

- Hygienic Surface Finishes Resist Bacterial Growth

Media Gallery

Resources

Overview

Marathon is designed to deliver the highest reliability of any distribution conveyor over long distances.

Key Differentiators

- Gate and Diverter Options to Meet Your Needs

- Long Run Maximizes Efficiency - Up to 30 Meters (100ft.) on a Single Unit

- Custom Designs From Simple to Complex

- Patented Stop/Start Method Improves Reliability and Performance

- Flexible Installation Minimizes Structural Support

- Lowest Downtime of Any Vibratory Conveyor Over 9 Meters (30ft.)

- Available with monobeam frames from 9 meters (30 Ft.) to 15 meters (50 ft.) long

- Monobeam design has a smaller footprint and provides better access for sanitation and maintenance